Management Summary

Permitting requirements and regulations like the corporate sustainability reporting directive (CSRD) increasingly require companies to put more attention to collecting relevant data, report on them and use the insights to make improvements. With the changing requirements (e.g. moving towards one point of contact for all permit related topics) and the growing attention of stakeholders and the society in general it becomes more challenging for management to decide which direction to choose and how to implement solutions to support the chosen direction.

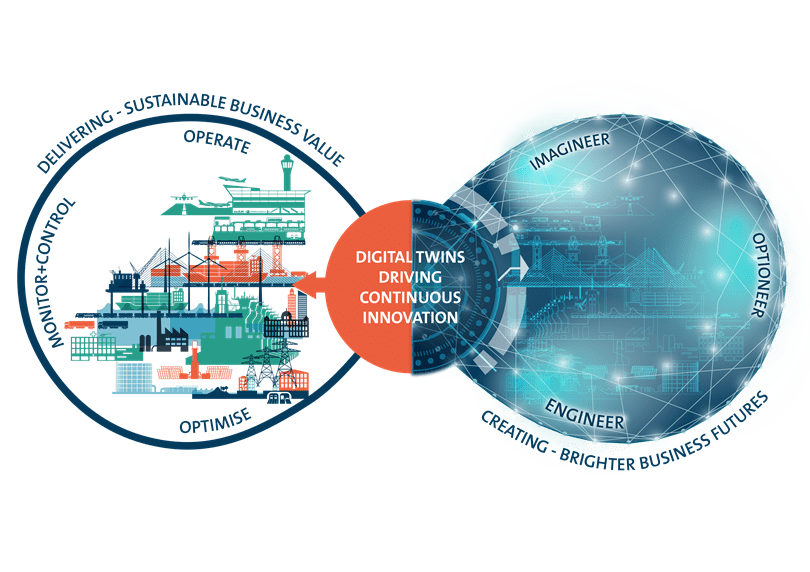

It is not new that companies are obligated to disclose information about the impact of their activities on people and the environment. In parallel corporates are urged to look for opportunities to decrease or change their energy consumption and reduce or compensate the emission of greenhouse gases and other pollutants. From a regulatory perspective historically so called ‘end-of-pipe’ monitoring and solution approaches were preferred. New regulations, permitting requirements and a growing emphasis on embedding sustainability in the organizational strategy have pivoted the focus to process-integrated approaches. Many companies do not have continuous emission monitoring and related reporting capabilities in place. Defining a strategy on how to handle both from a business process perspective, is an important starting point for an integrated approach.Therefore, emission monitoring and reporting is more than implementing a BI or reporting tool to measure certain output parameters and facilitate regulatory responsibilities. Increasingly near to real-time approaches in which mass balancing, tracing and tracking and energy and emission monitoring are combined are being developed and used. These allow meeting the combination of reporting and improvement requirements. Using Digital Twins is a good example of how to accomplish these integrated solutions. With the deep domain knowledge of our business lines and our digital consultancy capabilities we can support you to evaluate where process-integrated approaches and digital twins create value for your organization.

Challenges

Clients across various sectors, including process industries and real estate, face the imperative of measuring and reporting their environmental emissions. This includes emissions to air, water and soil and encompass carbon dioxide, nitrogenous compounds, potentially hazardous chemicals, noise, dust, effluents containing hazardous components, etc. Energy consumption and transportation may cause emissions by third parties, which may have to be allocated to the own balances as well. The purpose behind such reporting is twofold: to comply with regulations and secure necessary licenses, both of which involve critical process indicators and key performance indicators.